产品简介

微机控制和数显有关参数特制的机架,强度高,易调整,便于大漏底拆卸;封闭式圆墙板避免了墙版花;适用双棉卷或棉箱喂入;机外间歇吸,机内双滤尘箱连续吸;盖板倒转,增强分梳,改善棉网质量;设前后固定盖板及分梳板,锡林道夫结构

主要特点

●微机控制和工业触摸屏显示有关参数。

●锡林道夫结构优化设计,提高精度。

●特制的机架,强度高,易调整,便于大漏底拆卸

●盖板花剥取由抄刷辊取代上斩刀。

●封闭式圆墙板避免了墙板花。

●全机采用本厂设计生产的新型齿条。

●适应双棉卷或棉箱喂入。

●全新外观设计,美观大方。

●全机多吸点连续吸。

●四处自停,七处检测装置。

●盖板倒转,增强分梳,改善棉网质量。

●可以观察棉网的皮圈导棉装置.

●设前后固定盖板及分梳板。

详细说明

锡林、刺辊采用离心摩擦离合器及平皮带传动,结构简单,启动稳定。The consteuction of driving cylinder and licker-in by a friction clutch with centrifugal blocks and flat belt is simple and its starting is smooth and stable. 道夫采用变频电机,齿形带传动,实现无级调速。The doffer is driven by and electronic frequency converter and toothed belt . so as to its speed variation is stepless.. 给棉罗拉采用调频电机传动,实现无级变速,通过计算机控制与道夫传动同步。Feed roller is driven by an electronic frequency converter which permits stepless variation of its speed and is controled to be synchronized with doffer by the computer. 可视棉网的皮圈导棉装置,保证了棉条可以高速稳定运转,精心设计的大压辊具有自调匀整检测罗拉的功能。The web take-off unit allow visual inspection of the web,it ensures the web delivering in high speed and running very stable .The calender roller specially designed is the function of measuring roller for the autoleveller. 全机多吸点连续吸,压力连续检测。Multi suction point on card ,continuous suction ,pressure continuous measure. 菱形给棉罗拉,实现弹性握持,减少纤维损伤。The rhombus fluted-shaped feed roller holds the feed sliver slastically to decrease the damage to the fibre.

■ 电气控制 FA203A型梳棉机电气控制柜,采用进口PLC和两台进口变频器,控制道夫和给棉电机的无级调速和比例运转。升降速平滑,运行稳定可靠,刹车性能好。 机器的左前方安全罩上装有进口的显示屏,能控制开停各个电机,能显示各种动态的工艺数据,并能对各种故障和满筒等状态作出报警。整机的控制中心是进口可编程控制器,操作简单,运行可靠。Electric controlThere are one imported invers in the electronic control cabinet of card FA203A .it contronic doffer's and feed motor's speed to make a stepless variable speed and run it at the rate,with a smooth speed up and down and a good brake performance,it is running steady and reliable. The imported display screen is erected on safety cover in the left front of maching, It can control each motor. It can display all data on dynamic technology and take an alarm for all faults and full-can status. Control center of whole machine is a imported programmable controller,which operates simply and reliably.

■ 选用 清梳联喂棉箱JF1171型双箱气压式无回花喂棉箱,实现清花,梳棉连续化生产。YSD自调匀整系统,通过检测喂入棉层厚度和棉条厚度,由计算机控制给棉罗拉转速,实现长短片段匀整。 OptinalChute feed in blowroom & card line:JF1171 double-box air pressure type chute feed is without returning fibres to realize continuously production is blowroom and card line. YSD autolveller detects the thickness of feeding fibrous layers and controls the rotation of the feed roller by the computer and corrects for long and short term irregularities.

■ 结构示意图

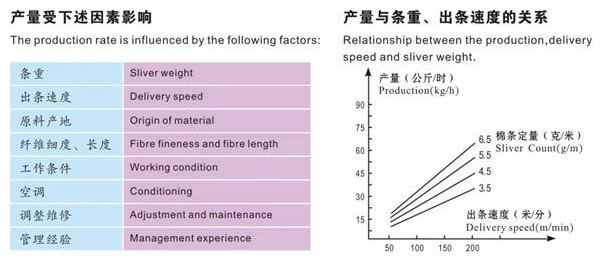

■ 产量与条重、出条速度的关系 技术参数适用范围本机适用于纤维长度22~76毫米的纯棉、化纤及其混纺。实际产量(公斤/小时)80(最高出条速度200米/分)棉条定量(克/米)3.5~6.5适用棉卷规格(毫米)最大直径550,宽度980工作幅宽(毫米)1000总牵伸倍数(毫米)60~300刺辊工作直径φ250刺辊工作速度756 833 942 1025转/分(皮带轮:φ224)771 771 872 942转/分(皮带轮:φ242)647 712 805 877转/分(皮带轮:φ262)道夫工作直径(毫米)φ706道夫工作速度(转/分)32-76锡林工作直径(毫米)φ1288锡林工作速度(转/分)纺棉 344 379 429 467纺化纤 300 331 374 407回转盖板根数(工作盖板/盖板总数)32/86盖板速度纺棉 145 160 181 198纺化纤 71 78 88 96附加梳理件刺辊分梳板、后固定盖板(3)、前固定盖板(3)适用棉条筒直径: φ600,φ900,φ1000高度: 1100,1200连续吸尘(米3/小时)风量3500出口静压(帕)>-920压缩空气(公斤/厘米2)压力4~5空气消耗(米3/小时)0.01总装机功率(千瓦)8.84主传动电机(千瓦)5.5道夫传动电机(千瓦)2.2清洁辊电机(千瓦)0.37盖板花清洁辊电机(千瓦)0.37给棉电机(千瓦)0.4安全罩形式全封闭式占地面积(长×宽)(毫米)3955x2048(不含圈条器)机器净重(公斤)7500

Copyright © 1999-2023 青岛青源纺织机械厂 All Rights Reserved. 山东省青岛市黄岛区海滨工业园 0532-86162769

鲁ICP备13018535号-3